Automatic mobile phone case DIY printer

As an emerging consumer terminal, the automatic phone case DIY printer integrates personalized customization technology with unmanned retail models. Its core experience can be summarized in the following dimensions:

1. Core Technology Principles

Contactless Digital Printing

Using UV inkjet technology, there is no need for plate making or repeated color registration. Full-color patterns can be printed directly on the surfaces of dozens of materials, including metal, glass, silicone, and TPU. The images are waterproof, UV-resistant, and wear-resistant.

Embossing Process Implementation

Through a dedicated color channel, white ink is printed in layers (3-5 layers), followed by a colored layer, creating a three-dimensional tactile embossed effect.

Smart Adaptation System

The MINI model is compact in size and features a built-in portable power source for mobile operations; the high-end model can handle cylindrical objects up to 20 cm in height and objects up to 17 cm in thickness.

2. User operation process

mermaid

Copy Code

graph LR

A[Select phone model] –> B[Upload/design pattern]

B –> C[Adjust size and positioning]

C –> D[Start printing]

D –> E[Collect finished product within 3 minutes]

Key Steps: Images must be processed using PS/CDR software to 300dpi resolution; vector graphics are preferred. The phone case surface must be thoroughly cleaned and positioned before printing.

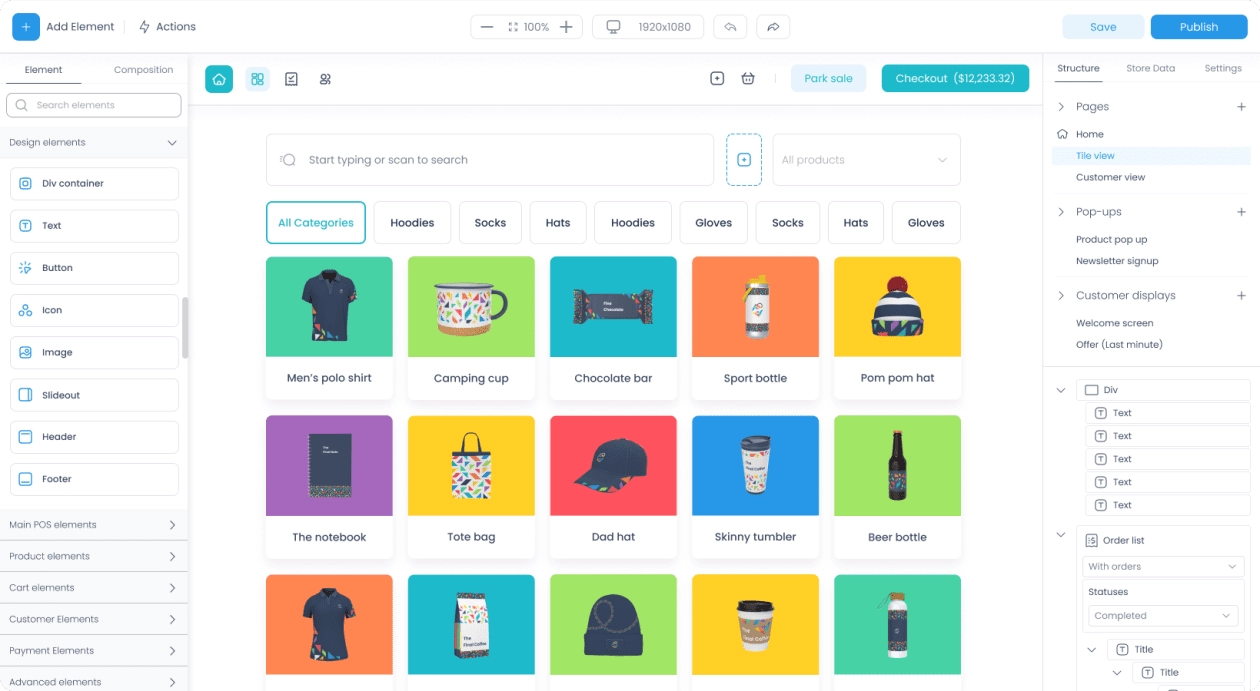

Interaction Simplification: The touchscreen interface integrates a pattern template library and supports real-time preview effects, lowering the operational threshold.

3. Commercial Value and Challenges

Advantages

Cost Efficiency: Eliminates the limitations of screen printing mass production, with minimum order quantities starting at a single piece, on-demand printing and pickup, and a 50% reduction in labor costs

Customer Appeal: Meets the “exclusive customization” needs of young people, with a single machine capable of processing up to 100 orders per day in popular commercial districts

Scene Adaptability: Supports deployment in multiple scenarios such as mall pop-up stores, cultural and creative markets, and tourist souvenir shops

Pain Points

Model Compatibility Limitations: Mainstream devices are only compatible with popular models like Apple, with insufficient coverage for Android models

Failure Rate Risk: Issues such as nozzle blockages and uneven white ink layering require regular maintenance, affecting user experience

Environmental Requirements: UV curing requires avoidance of strong light, and dust contamination can cause printing defects

4. Consumer Experience Samples

Tokyo Shibuya Pop-Up Store Case Study:

German tourists draw abstract graffiti on the touchscreen → select the “neon glow-in-the-dark ink” option → upon completion, the machine plays an electronic sound effect and displays a thank-you card. The embossed texture glows in the dark, sparking social media check-ins and sharing

5. Evolutionary Trends

Semi-self-service optimization: Add remote video guidance functionality to address operational barriers for elderly users;

Material Breakthroughs: Develop more flexible ink compatible with foldable phone cases

Data Analysis: AI records regional pattern preferences and dynamically updates the design library (e.g., Parisian neighborhoods prefer art collaboration editions)

This device is fundamentally a product of the “instant gratification economy”—fragmenting the trillion-dollar smartphone accessory market. Its success hinges on the precise balance between technological stability and scenario insights.